Qúy khách đang có nhu cầu tìm hiểu về tủ điện công nghiệp để trang bị cho hệ thống điện, máy móc, và dây chuyền của nhà máy của quý khách? Qúy khách đang phân vân không biết nên chọn loại tủ điện công nghiệp nào tốt, an toàn và phù hợp với ngân sách? Hãy để FERMENTUM giải đáp thắc mắc của quý khách về tủ điện công nghiệp ngang qua bài viết sau đây:

Tủ điện công nghiệp là loại tủ điện được sử dụng trong môi trường công nghiệp và đáp ứng các tiêu chuẩn của công nghiệp. Khác với tủ điện dân dụng thông thường, tủ điện công nghiệp sẽ có những tiêu chuẩn cao hơn, với các thiết bị có công suất lớn, và hệ thống điều khiển cao cấp hơn.

Có nhiều cách phân biệt và phân loại tủ điện công nghiệp khác nhau, tùy vào nhu ứng dụng và nhu cầu sử dụng của người dùng mà bên sản xuất sẽ cung cấp các loại tủ điện khác nhau, như tủ điện phân phối, tủ điện điều khiển, tủ điện trong nhà, tủ điện ngoài trời….

Sau đây FERMENTUM xin giới thiệu một số loại tủ điện công nghiệp phổ biến nhất hiện nay:

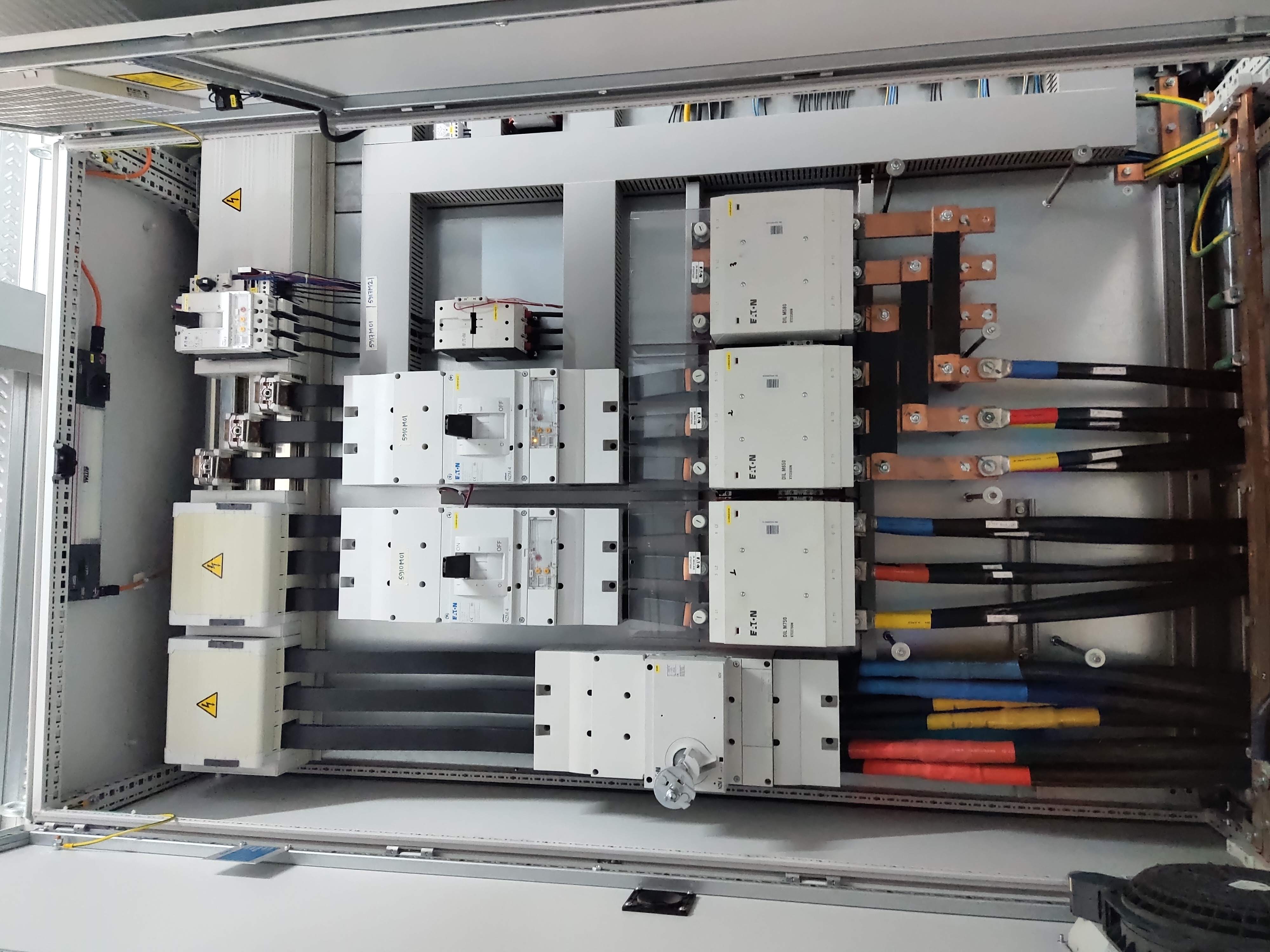

Tủ điện phân phối chính, Tiếng Anh là Main Distribution Switchboard (MSB) hay còn gọi là tủ điện chính, tủ điện tổng hay tủ phân phối chính, đóng vai trò là tủ đầu vào cho toàn bộ hệ thống điện hạ thế của một cơ sở. Tủ điện MSB chính là loại tủ điện được lắp đặt ngay sau các trạm biến áp hạ thế và trước các tủ điện phân phối MDB/DB.

Tủ điện MSB thường được thiết kế với nhiều ngăn, trong mỗi ngăn sẽ có những chức năng riêng biệt như ngăn chứa máy cắt chính (ACB), ngăn để chứa MCCB/MCB tổng, ngăn chứa MCCB/MCB ngõ ra tải, ngăn chưa tủ bù, ngăn chứa nguồn ATS,...

Vì là tủ phân phối chính, có nhiệm vụ bảo vệ cho toàn bộ hệ thống điện hạ thế của một cơ sở, nên tủ MSB luôn được các chuyên gia và kỹ sư tính toán và thiết kế cẩn thận, với các tiêu chuẩn kỹ thuật cao nhất.

Tủ điện phân phối DB có tên tiếng Anh là Distribution Board, đây là một tủ điện trong hệ thống điện được sử dụng để phân phối và điều khiển điện năng đến các thiết bị, máy móc và hệ thống khác trong một tòa nhà hoặc khu vực sử dụng. Vị trí được lắp đặt của tủ điện phân phối DB được lắp đặt sau tủ MSB hoặc MDB (nếu có).

Loại tủ này được thiết kế nhỏ gọn, với thành phần chính là máy cắt (ACB), MCCB/MCB, cầu chì, đèn báo pha, và đồng hồ hiển thị chỉ số điện năng. Với đồng hồ điện năng, doanh nghiệp có thể dùng PLC để truy vấn các thông số điện năng, từ đó doanh nghiệp có thể quản lý và giám sát các chỉ số điện năng đó thông qua hệ thống SCADA.

Tủ điện điều khiển động cơ MCC tên gọi tiếng Anh là Motor Control Center, đây là một loại tủ điện chuyên dụng được sử dụng để điều khiển và bảo vệ động cơ điện (bảo vệ ngắn mạch, quá tải, mất pha, quá áp hoặc thấp áp…)

Tủ MCC được sử dụng trong các ứng dụng công nghiệp, như nhà máy sản xuất, xí nghiệp chế biến, trạm biến áp, các tòa nhà lớn, các hệ thống chạy liên tục, và các ứng dụng điện năng khác. Tủ điện MCC được thiết kế và lắp đặt tại các trung tâm điều khiển của hệ thống động cơ.

Các phương thức khởi động và điều khiển phổ biến tùy thuộc vào chủng loại động cơ và bài toán của nhà máy:

- Khởi động trực tiếp (DOL - Direct on line)

- Khởi động sao – tam giác (Star - Delta)

- Khởi động mềm (Softstarter)

- Biến tần (VFD - Variable Frequency Drive)

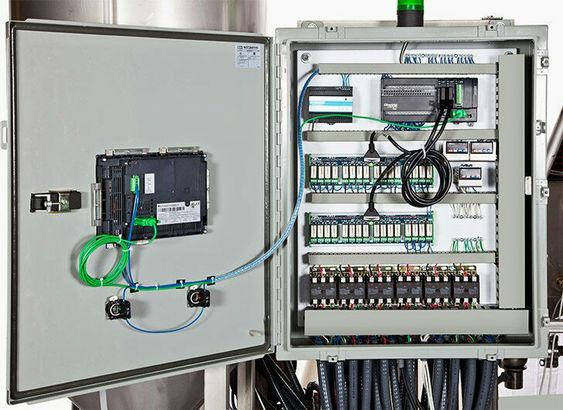

Tủ điện được gọi là tủ điện điều khiển PLC vì trong tủ điện này có PLC và chức năng của nó là đóng vai trò điều khiển trung tâm cho cụm thiết bị, bao gồm các thiết bị đóng cắt và thiết bị ngoại vi (cảm biến, van,…).

Tủ PLC thường được thiết kế nhỏ gọn, tối ưu về không gian. Thành phần chủ yếu của tủ điện PLC là thiết bị PLC, bộ nguồn, cầu chì, rơ le, thiết bị bảo vệ…. Và một thành phần không thể thiếu đó là phần mềm, đó là chương trình được nạp cho PLC để PLC vận hành và điều khiển các thiết bị.

Một đặc điểm khác của tủ PLC là sự linh hoạt của nó. Nếu trong tương lai, doanh nghiệp có nhu cầu mở rộng cụm thiết bị, hay quy mô nhà máy. Thì doanh nghiệp chỉ cần đầu tư mua thêm một vài linh kiện bổ sung và dễ dàng thay đổi, cập nhật chương trình, mà không cần phải mua một tủ PLC mới. Đó là sức mạnh và ưu điểm của PLC.

Tủ điện cục bộ – LOP với tên gọi Tiếng Anh là Local Operating Panel. Đóng vai trò là tủ trung gian giữa tủ điện PLC và các thiết bị ngoại vi.

Lợi ích của tủ điện LOP:

- Tủ LOP giúp doanh nghiệp tiết kiệm chi phí cáp điện: Vị trí lắp đặt của tủ điện cục bộ – LOP thường là gần với các cụm thiết bị ngoại vi (cảm biến, van,…) nên một tủ LOP sẽ đóng vai trò quản lý, thu tập các tín hiệu của tất cả các thiết bị ngoại vi đó và gửi tín hiệu về tủ điện điều khiển trung tâm thông qua mạng truyền thông để xử lý.

- Tủ điện cục bộ giúp đội ngũ quản lý dễ dàng quản lý tín hiệu, xử lý tín hiệu của cụm thiết bị.

- Tiết kiệm thời gian và tăng độ chính xác trong quá trình bảo trì và sửa lỗi.

Tủ điện chuyển nguồn tự động ATS tên Tiếng Anh là Automatic Transfer Switch, đây là một loại tủ điện được sử dụng để chuyển đổi nguồn điện giữa nguồn điện chính và nguồn điện dự phòng khi có sự cố xảy ra.

Tủ ATS được sử dụng trong các hệ thống cung cấp điện dự phòng để đảm bảo rằng nguồn điện sẽ luôn được cung cấp cho các thiết bị quan trọng trong trường hợp nguồn điện chính bị mất đi. Tủ ATS được sử dụng trong các ứng dụng quan trọng như các nhà máy, bệnh viện, trung tâm dữ liệu, các tòa nhà lớn, và các ứng dụng khác yêu cầu độ tin cậy cao trong việc cung cấp điện. Việc sử dụng tủ ATS giúp đảm bảo rằng các thiết bị quan trọng sẽ luôn được cung cấp nguồn điện, đồng thời giảm thiểu rủi ro và thời gian gián đoạn trong hoạt động của hệ thống.

Thành phần thiết bị chính của tủ chuyển nguồn tự động – ATS

- Nút nhấn: có thể lựa chọn phương án tự động hoặc bằng thủ công

- Màn hình LCD.

- Hệ thống đèn báo xanh đỏ.

- Vỏ tủ điện.

- Bộ điều khiển tủ điện, thiết bị chuyển mạch tự động

Tủ điện chiếu sáng thông minh sử dụng các bộ điều khiển đóng cắt theo thời gian thực trong ngày, hoặc theo tuần để đóng cắt các đèn chiếu sáng. Ở cấp quản lý đồng bộ nhà máy, tủ chiếu sáng có thể thiết kế để kết nối với hệ thống SCADA để nhà máy có thể quản lý, giám sát và điều khiển toàn bộ hệ thống chiếu sáng của tổ chức.

Các chế độ làm việc thông thường:

- Chế độ điều khiển tập trung: Điều khiển tập trung từ trung tâm, tự động báo lỗi về trung tâm điều khiển.

- Chế độ điều khiển tự động: Thời gian hoạt động có thể tùy chỉnh lại được theo ý muốn.

- Chế độ điều khiển bằng tay: Dùng trong các trường hợp cần điều khiển trực tiếp.

- Tủ điện phải được tính toán, lựa chọn và thiết kế phù hợp với yêu cầu. Muốn vậy, bước tính toán và thiết kế tủ điện phải được tiến hành kỹ lưỡng và cẩn thận. Các thông số kỹ thuật của thiết bị phải đáp ứng và tương thích với bài toán đã đưa ra.

- Các thiết bị trong tủ điện phải chất lượng, có nguồn gốc xuất xứ từ các nhà sản xuất cung cấp uy tín hàng đầu. Một thiết bị tốt sẽ đảm bảo hệ thống điện của tổ chức được hoạt động ổn định và được bảo vệ tốt. Đi kèm với đó các thiết bị trong tủ điện phải có các chứng chỉ CO/CQ, Test report đầy đủ. Một số nhà sản xuất thiết bị công nghiệp hàng đầu hiện nay bao gồm: Siemens, Schneider, Eaton, Mitsubishi, LS,…

- Vỏ tủ điện công nghiệp có độ dày đảm bảo và chắc chắn. Vỏ tủ điện giúp bảo vệ các thiết bị bên trong tủ điện tránh khỏi các tác nhân bên ngoài. Góp phần tăng tuổi thọ và độ bền của thiết bị bên trong.

- Thiết kế tủ điện công nghiệp đẹp và logic: Một tủ điện đẹp, đầy đủ thông tin và logic giữa các tầng thiết bị sẽ tạo cho người vận hành cảm giác thoải mái và yêu thích công việc hơn. Đồng thời, đây là yếu tố giúp giảm thời gian và tăng hiệu quả trong vận hành, bảo trì hơn.

- Tủ điện công nghiệp có giá cả phù hợp với ngân sách.

Chúng tôi với đội ngũ kỹ sư chuyên môn sâu và nhiệt thành, đã có nhiều kinh nghiệm trong việc thiết kế, cung cấp và lắp đặt cho các tập đoạn, công ty lớn trong và ngoài nước. Chúng tôi luôn tiên phong trong vấn đề nghiên cứu và cập nhật công nghệ mới. Nhằm mang lại nhiều hơn các giá trị sâu sắc cho quý khách hàng.

- Tác phong làm việc chuyên nghiệp, chân thành và chín chu.

- Quy trình làm việc bài bản và chuyên nghiệp.

- Là đối tác chiến lược của các hãng sản xuất, cung cấp thiết bị công nghiệp hàng đầu. Vì vậy, sản phẩm của chúng tôi luôn có một mức giá cạnh tranh trên thị trường.

- Sự an toàn, độ tin cậy và bảo mật thông tin luôn được chúng tôi ưu tiên hàng đầu.

Vì vậy, quý doanh nghiệp có nhu cầu về tủ điện công nghiệp vui lòng liên hệ với chúng tôi để được tư vấn và báo giá tủ điện công nghiệp. Chúng tôi luôn sẵn sàng lắng nghe và hân hạnh được phục vụ quý khách.

Bài viết liên quan đến chủ đề: