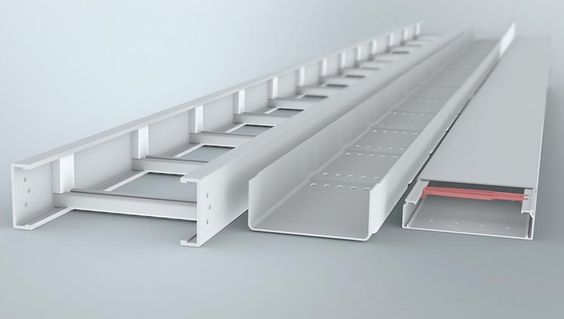

The cable tray system is an important and indispensable part of electrical installations in high-rise buildings, factories, or office buildings... So, how do we classify cable trays? What should be noted when choosing cable trays? How to install them to ensure requirements are met? Let’s explore these questions in this article.

This type is coated with powder using modern technology and is primarily used for indoor installations.

Advantages:

- High aesthetic value

- Wide variety of colors

- Cost-effective

- Quick production time, suitable for projects with tight deadlines

Disadvantages:

- Low corrosion resistance, making it unsuitable for outdoor electrical installations. It should only be used for indoor applications.

This type is dipped in a bath of molten pure zinc (at least 98%). Hot-dip galvanized cable ladders/trays are often used for outdoor installations or in corrosive environments.

Advantages:

- Extremely durable coating, preventing peeling and ensuring a long lifespan

- High resistance to corrosion and wear, offering excellent rust protection

Disadvantages:

- The price of hot-dip galvanized cable ladders/trays is relatively high.

- The surface of the hot-dip galvanized coating is rough. The galvanized finish is not shiny and quite dull, which reduces the aesthetic appeal of the product.

- It is only available in one color, the silver-gray of the zinc coating.

Advantages:

- Good rust resistance, high corrosion, and abrasion resistance.

- The surface of this type of cable ladder/tray is shiny and smooth after galvanizing, providing a high aesthetic appeal.

- The product is low-cost.

Disadvantages:

- The coating is thin, making it easy to scratch and not very durable.

- It only comes in one color, the bright silver of the zinc coating.

ZAM steel is an alloy of Zinc, Aluminum, and Magnesium. It has a higher corrosion resistance compared to regular galvanized steel. ZAM steel cable ladders/trays typically have properties similar to electro-galvanized ones, making them relatively inexpensive.

Advantages:

- The product cost is reasonable.

- High resistance to abrasion, corrosion, and rust.

- The surface of this type of cable ladder/tray is shiny and smooth, providing a high aesthetic appeal.

Disadvantages:

- The surface is easily scratched during manufacturing and installation.

- It only comes in one color, the bright silver of the zinc layer.

These products are mainly made from stainless steel (non-rusting steel).

Advantages:

- High durability and resistance to rust.

- They do not fade or wear down, thus extending the lifespan of the electrical system significantly.

- Simple and lightweight design, allowing for quicker installation and time savings.

Disadvantages:

- The product is expensive.

- Stainless steel 201 cable ladders/trays should only be used for indoor projects. For outdoor electrical projects, stainless steel 304 is recommended. However, this type is easily corroded by chloride ions, so it is rarely chosen for seaside installations.

- Width – W (Width): The width of the cable ladder/tray depends on the current quantity and size of the cables, as well as future expansion plans for the organization.

- Environment: Depending on the installation environment, choose the appropriate type of cable ladder/tray, optimizing for cost.

- Budget: Depending on the organization's budget, choose the appropriate type of cable ladder/tray. However, customers should prioritize technical considerations in the process of selecting cable ladders/trays.

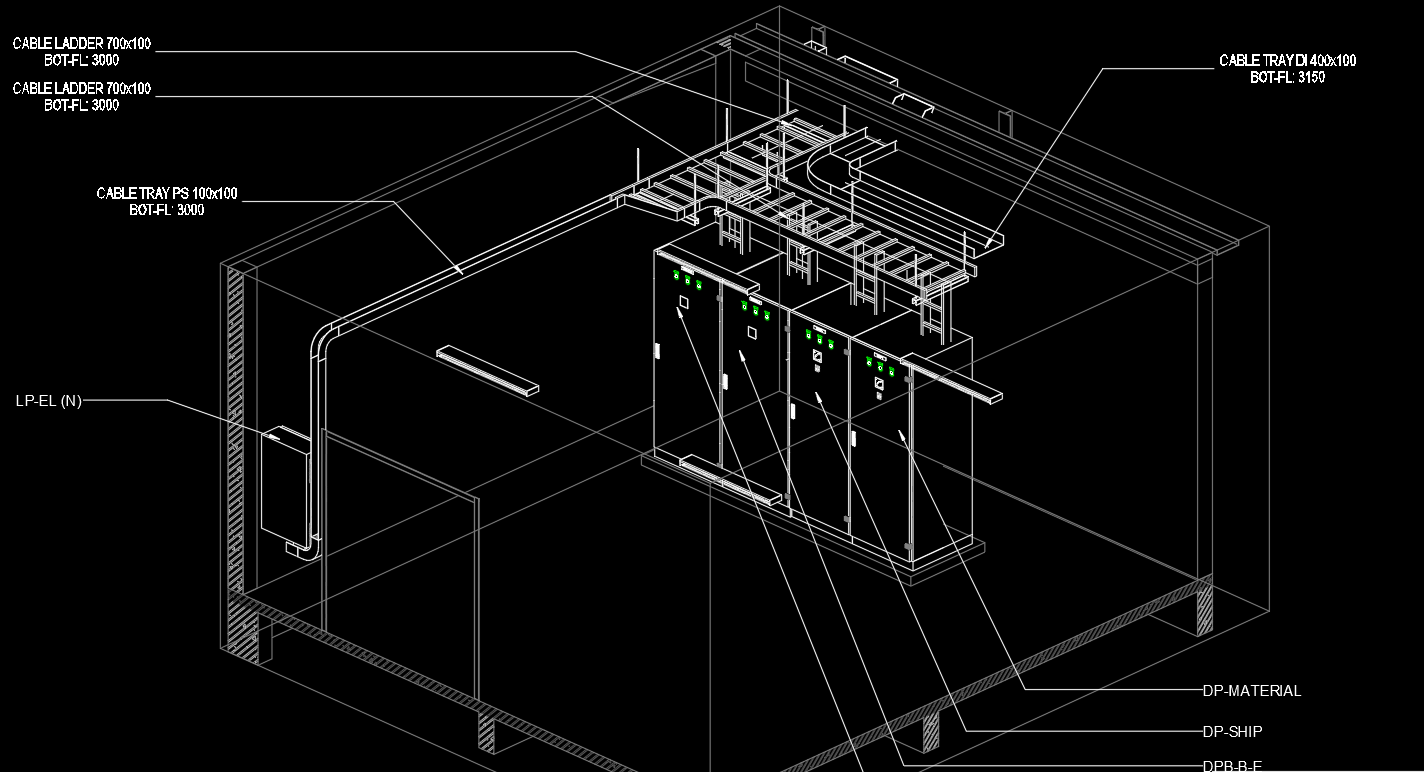

Installing a cable ladder/tray system is one of the initial steps in the process of electrical system installation for a project. If the cable ladder/tray system is installed correctly and according to standards, it contributes to protecting and managing the electrical wiring system safely and ensures the stability of the electrical system operation.

- Preparation stage: Before installing the cable ladder/tray system, it is necessary to conduct a detailed survey of the cable ladder/tray route and proceed with caution. This helps to avoid any obstacles caused by other systems in the project.

- Always prioritize safety: Because cable ladder/tray systems are often installed at heights, working at heights must comply with safety regulations and climbing rules.

- Install sufficient support brackets, ensuring structural integrity.

- Pay attention to factors affecting the aesthetic appeal of the cable ladder/tray system, such as avoiding sloping installation or installation at non-optimal heights.

We are a specialized contractor in designing, supplying, and installing cable ladder/tray systems.

- With our team of highly skilled engineers who are experienced in providing and installing systems for large corporations both domestically and internationally, we meet the stringent requirements of foreign customers.

- Our professional, sincere, and meticulous work ethic sets us apart.

- We follow a systematic and professional work process.

- We are strategic partners of leading industrial equipment manufacturers and suppliers.

- Workplace safety and hygiene are paramount to us.

We will help you save time and costs while ensuring your satisfaction and peace of mind when using our services.

Therefore, if you have any need for cable ladder/tray installation, do not hesitate to contact us. We are always ready to listen and honored to serve you.