The grounding and lightning protection system is an essential electrical safety system in factories and buildings. An effective grounding and lightning protection system helps protect equipment, machinery, and electrical systems within the organization, but most importantly, it ensures safety for people. What is the grounding and lightning protection system? What are its functions and components? What technical standards need to be considered when installing the grounding and lightning protection system? Let's explore these questions with FERMENTUM in this article!

The grounding or earthing system is a system designed to dissipate fault currents into the ground and maintain low voltage levels across electrical systems, electrical equipment components, and metallic enclosures connected to it. Electrical faults commonly occur, such as insulation breakdown, short circuits, phase-to-ground faults, and lightning strikes.

Therefore, the grounding system is crucial for protecting against overvoltages for electrical systems and equipment. Based on their operational functions and applications, the grounding system is divided into the following three types:

Functional Grounding System:

Tiếp địa làm việc nhằm đảm bảo điều kiện làm việc bình thường cho thiết bị điện và một số bộ phận của thiết bị điện theo chế độ làm việc đã được quy định sẵn. Đây là loại tiếp địa bắt buộc để đảm bảo các điều kiện vận hành của hệ thống. Loại nối đất này gồm: nối đất điểm trung tính máy biến áp trong hệ thống điện có điểm trung tính nối đất; nối đất máy biến áp đo lường của các kháng điện dùng trong các thiết bị bù ngang trên đường dây truyền tải điện đi xa.

Functional grounding ensures normal operating conditions for electrical equipment and certain components of the equipment according to predetermined operating modes. This type of grounding is mandatory to ensure the operational conditions of the system. This type includes grounding for the neutral point of the transformer in systems with neutral grounding and grounding for measuring transformers used in shunt reactors on long-distance power transmission lines.

Safety Grounding System:

Safety grounding aims to protect individuals when in contact with the insulation of electrical equipment in case of damage. Safety grounding is achieved by connecting all metal parts of electrical equipment or metal structures to the grounding system. When insulation is damaged, these parts may become energized, but due to being grounded, the voltage level remains low, ensuring safety for individuals.

Lightning Protection Grounding System

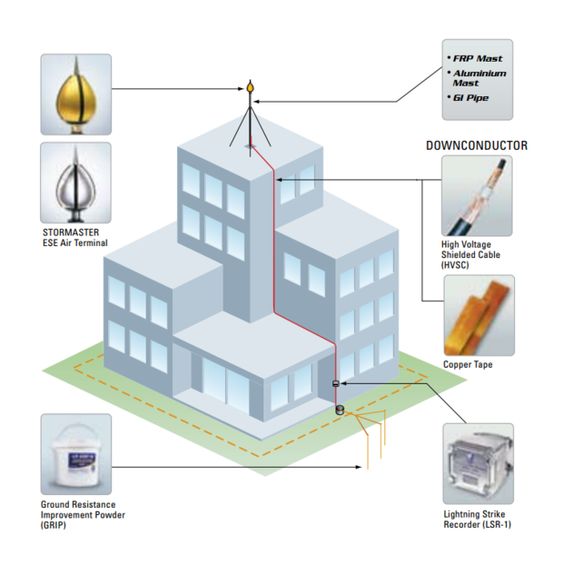

Lightning protection grounding connects the components of the lightning protection system, such as lightning rods, lightning receptors, or lightning conductors, to the grounding system. This is to dissipate lightning currents into the ground when lightning strikes the lightning rod, overhead power lines, or substations. The purpose is to keep the voltage at any point on the grounding system low to prevent reverse electrical discharge from that element to the electrically protected components.

The grounding system includes:

- Grounding rods, copper-bonded grounding rods

- Junction boxes

- Grounding wires

- Cables connected to electrical equipment

- Chemicals for reducing resistance

Supporting materials for the construction process include:

- Heat welding molds

- Heat welding flux

- Quality resistance measuring instruments

General requirements specified in TCVN 9358:2012 regulations for installing grounding systems for industrial projects.

Equipment distribution regulations and substations are specified in Article 11 of TCN-20:2016,

Protection and automatic regulations are specified in Article 11 of TCN-21:2016.

Vietnam Standard TCVN TCVN 4756:1898

In addition, customers need to consult with suppliers when installing automatic machinery to consider their specific requirements for the grounding system. Typically, manufacturers, especially those from European and American countries, have their standards and requirements.

According to the regulations of Vietnam Standard TCVN 4756:1898

- The independent ground resistance should not exceed 10 (Ohms).

- The independent safety ground resistance should be ≤ 4 (Ohms).

- The ground resistance for independent AC currents should be ≤ 4 (Ohms).

- The ground resistance for independent DC currents should not exceed 4 (Ohms).

- The static ground resistance typically should not exceed 100 (Ohms).

- The common ground connection positions should not be greater than 1 (Ohm).

- The ground resistance for AC currents should not exceed 4 (Ohms), and the safety resistance should not exceed 4 (Ohms).

- The lightning protection resistance should not exceed 10 (Ohms), and the ground resistance should be under 10 (Ohms).

- The grounding system's ground resistance should meet the requirement: R≤2000 / IΩ. When load> 4000A, R≤0.5Ω.

- In cases where the system uses devices under 1000V, the resistance value must comply with R≤125 / IΩ.

The ground pile driving system is for projects with a lot of empty land around or projects that are just starting construction, with foundations that can be driven into the ground.

Step 1: Digging trenches for the grounding system.

- Determine the location and mark it. Check carefully before digging to avoid other underground structures such as underground cables or water systems.

- Dig trenches from 600mm - 800mm deep, and 300mm - 500mm wide, with lengths and shapes according to the design drawings or actual construction sites.

Step 2: Burying electrodes in the ground

- Drive ground rods at specified locations so that the distance between the rods is twice the length of the rod driven into the ground. However, in areas with limited grounding system space, the rods can be driven closer together (but not less than 1 times the length of the rod).

- Drive the rods until the top of the rod is 100mm to 150mm above the bottom of the trench.

- The central ground rod is driven shallower than the others so that the top of the rod is 150 ~ 250mm above the ground to allow the rod to be inside the inspection pit when checking the ground resistance.

- Lay stranded copper wire along the trenches to connect to the driven rods.

- Pour the chemical to reduce ground resistance along the stranded copper wire or before driving the rod, dig deep at the rod location with a pit diameter from 200mm to 300mm, depth 500mm from the bottom of the trench, and pour the chemical into these pits. The ground resistance-reducing chemical will absorb moisture to form a glue-like substance around the electrode, increasing the contact surface area between the electrode and the ground, reducing the ground resistance, and protecting the grounding system.

- In the case of well drilling, the ground rods will be directly connected to the cable to be lowered deep into the well.

- Pour the ground resistance-reducing chemical into the well, and pour water to allow the chemical to settle deeper into the well bottom.

Step 3: Selecting and installing lightning rods

- Lightning rods made of metal with a length of 0.5-1.5m are installed on the roof. Connect the lightning rod to the grounding wire going down to the ground. The lightning discharge wire is connected to the ground rod. The ground terminal is metal bars about 2.5-3m long buried deep into the ground at a distance of 1-2m outside the floor.

- The direct lightning conductor wire from the lightning rod or the ground wire from the main grounding copper plate will be connected to the grounding system at the ground resistance test box location.

Bước 4: Hoàn trả mặt bằng hệ thống tiếp đất

- Lắp đặt hố kiểm tra điện trở đất tại vị trí cọc trung tâm sao cho mặt hố ngang với mặt đất.

- Kiểm tra lần cuối các mối hàn và thu dọn dụng cụ.

- Đo điện trở tiếp đất của hệ thống, giá trị điện trở cho phép là < 10 Ohm, nếu lớn hơn giá trị này thì phải đóng thêm cọc, xử lý thêm hóa chất giảm điện trở đất hoặc khoan giếng để giảm tới giá trị cho phép.

- Lấp đất vào các hố và rãnh, nện chặt và hoàn trả mặt bằng.

Step 4: Restoring the ground system surface

- Install the ground resistance test pit at the central rod location so that the pit surface is level with the ground surface.

- Check the final welds and clean-up tools.

- Measure the ground resistance of the system, the allowable resistance value is <10 Ohms, if greater than this value, additional rods must be driven, additional ground resistance-reducing chemicals applied, or wells drilled to reduce to the allowable value.

- Fill soil into pits and trenches, tamp down tightly, and return to the ground surface.

As it is an important protective system, we encourage customers to use high-quality materials and equipment from reputable leading brands. Notable examples include Cavanloi (Vietnam), Ingesco (Spain, with over 50 years of operation), Kumwell (Thailand), LPI (Australia),...

Currently, there are many contractors specializing in lightning and grounding systems. However, to save time and costs, you can consider our services. FERMENTUM specializes in designing, supplying, and installing lightning and grounding systems.

- With a team of highly skilled engineers and extensive experience in implementing numerous projects.

- Professional, sincere, and meticulous work ethic.

- Standard and professional work processes.

- Strategic partner of leading lightning and grounding equipment manufacturers. Therefore, our products always have a competitive price in the market.

- Safety, reliability, and information security are our top priorities.

Therefore, any customers in need of lightning and grounding rods, related materials for lightning and grounding systems, or lightning and grounding system construction, please contact us for consultation and quotation. We are always ready to listen and honored to serve our customers.