Doanh nghiệp Quý khách đang có nhu cầu thiết kế và lắp đặt hệ thống SCADA với tính bảo mật cao, hoạt động ổn định, nhiều chức năng chuyên sâu, giá cả hợp lý và đặc biệt là dịch vụ hỗ trợ kỹ thuật 24/7 để mang lại sự an tâm cho Doanh nghiệp Qúy khách. Hãy cùng FERMENTUM tìm hiểu về hệ thống SCADA và nếu được hãy để Chúng tôi phục vụ nhu cầu của Qúy khách.

Hệ thống Điều khiển giám sát và thu thập dữ liệu – SCADA, nguyên văn Tiếng Anh là Supervisory Control and Data Acquisition. Như chính tên gọi của nó, hệ thống SCADA được sử dụng để điều khiển, giám sát và phân tích, thu thập dữ liệu của các thiết bị công nghiệp cũng như của quá trình công nghệ. Hệ thống SCADA bao gồm phần mềm và phần cứng (Server, Máy tính, bộ điều khiển, truyền thông và các thiết bị ngoại vi…). Từ đó, nó cho phép các kỹ sư cũng như người điều hành có thể điều khiển, quản lý từ xa mà không cần trực tiếp đến thiết bị.

Đúng như tên gọi của nó, SCADA cho phép các doanh nghiệp:

- Kiểm soát các quy trình công nghệ tại chỗ hoặc từ xa

- Theo dõi, thu thập và xử lý dữ liệu theo thời gian thực.

- Kết nối với các thiết bị ngoại vi như cảm biến, van, động cơ, biến tần, cân định lượng…

- Ghi/nhận sự kiện như báo lỗi, cảnh báo cho người dùng, … và đồng thời cho phép Kỹ sư ghi lại và lưu trữ các thông tin đó.

Từ đó, SCADA giúp các doanh nghiệp:

- Cải tiến quy trình hoạt động: thông qua việc thu thập, lưu trữ và phân tích dữ liệu, giúp nhà quản lý có đủ thông tin để cải thiện quy trình tốt hơn với chi phí thấp hơn mà lại hiệu quả hơn.

- Nâng cao năng suất: nhờ quá trình phân tích các quy trình sản xuất, nhà quản lý có thể dùng các thông tin này để nâng cao năng suất sản xuất.

- Cải thiện chất lượng sản phẩm: cũng thông qua việc phân tích các hoạt động, xử lý tình huống kịp thời, nhà quản lý có thể tìm cách hạn chế, ngăn chặn các sai sót, giảm lượng sản phẩm bị lỗi hỏng trong quá trình sản xuất.

- Giảm thời gian và chi phí vận hành, bảo trì: thông qua việc thu thập dữ liệu theo thời gian thực, đồng thời với chức năng cảnh báo lỗi chính xác giúp người vận hành biết được chính xác vấn đề đang gặp phải (nếu có), đồng thời ra quyết định chính xác và nhanh hơn.

- Hệ thống SCADA tăng tính an toàn và bảo mật: hệ thống SCADA thay thế con người để giám sát và điều khiển máy móc tại những khu vực nguy hiểm và độc hại, đồng thời hạn chế sự cố trong quá trình vận hành.

- Bảo toàn vốn đầu tư: SCADA kết hợp với hệ thống Tự động hóa sẽ giúp doanh nghiệp giảm chi phí nhân công và chi phí vận hành nhờ công nghệ điều khiển tập trung. Hơn nữa, hệ thống SCADA có thể tùy chỉnh, sửa đổi và cập nhật theo yêu cầu và quy mô của doanh nghiệp mà không làm mất đi sự hiệu quả của nó...

Có nhiều cấu trúc SCADA khác nhau tùy theo nhu cầu, quy mô của mỗi doanh nghiệp. FERMENTUM xin giới thiệu một vài mô hình điển hình và thông dụng nhất hiện nay:

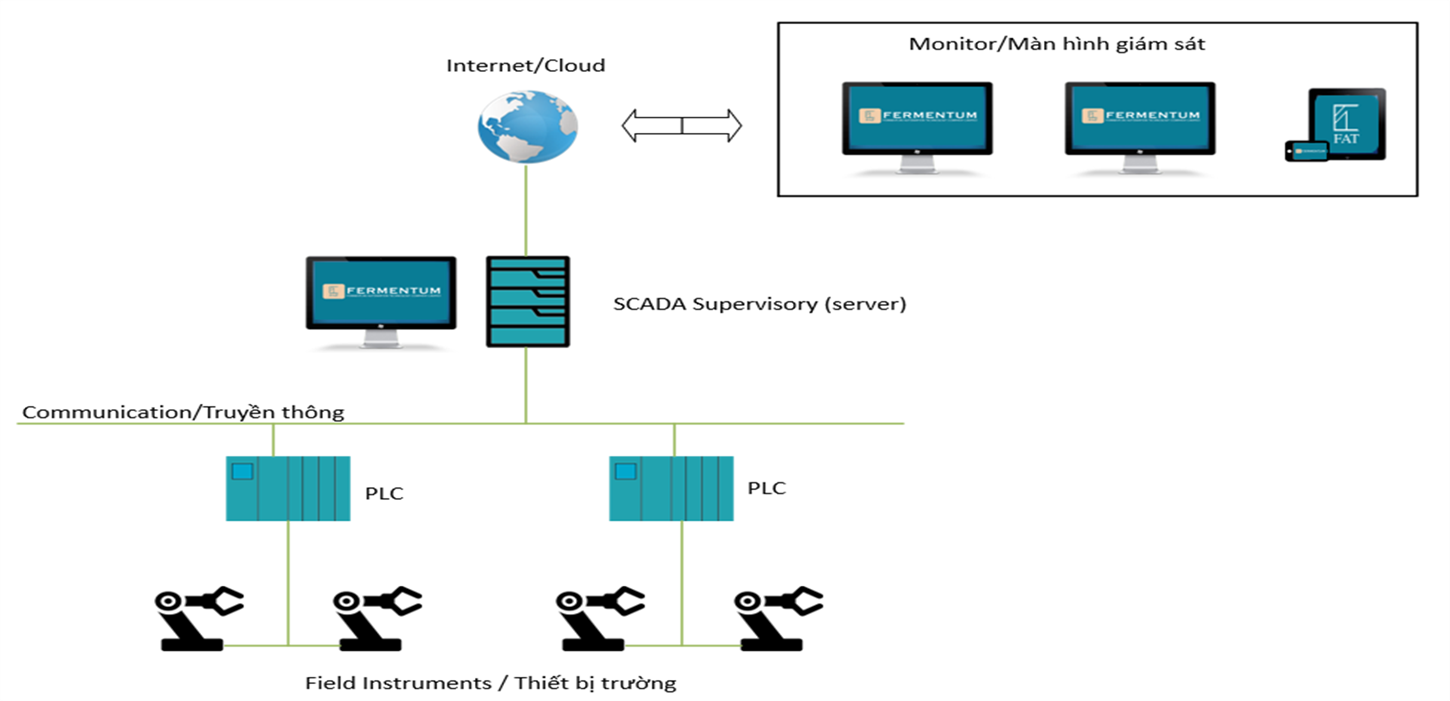

Cấu trúc hệ SCADA cơ bản

- Monitor/ Màn hình giám sát: Giám sát liên tục các thông số vật lý. Ở đây Monitor có thể là PC/HMI/Máy tính bảng/Điện thoại…

- SCADA Server: Phần mềm SCADA được cài đặt trên PC

- Controler/PLC: Giám sát và kiểm soát quy trình theo thời gian thực

- Communication/Mạng truyền thông: Tùy thuộc cấu trúc, yêu cầu của nhà máy, và sự tương thích với PLC cũng như các thiết bị trường của nhà máy đang/sẽ sử dụng để lựa chọn mạng truyền thông phù hợp. Tiêu biểu có Profinet, Profibus, CC-Link,...

- Field Instruments/Thiết bị trường: Bao gồm các cơ cấu chấp hành như Valve, Biến tần, động cơ... và thiết bị đo lường như cảm biến.

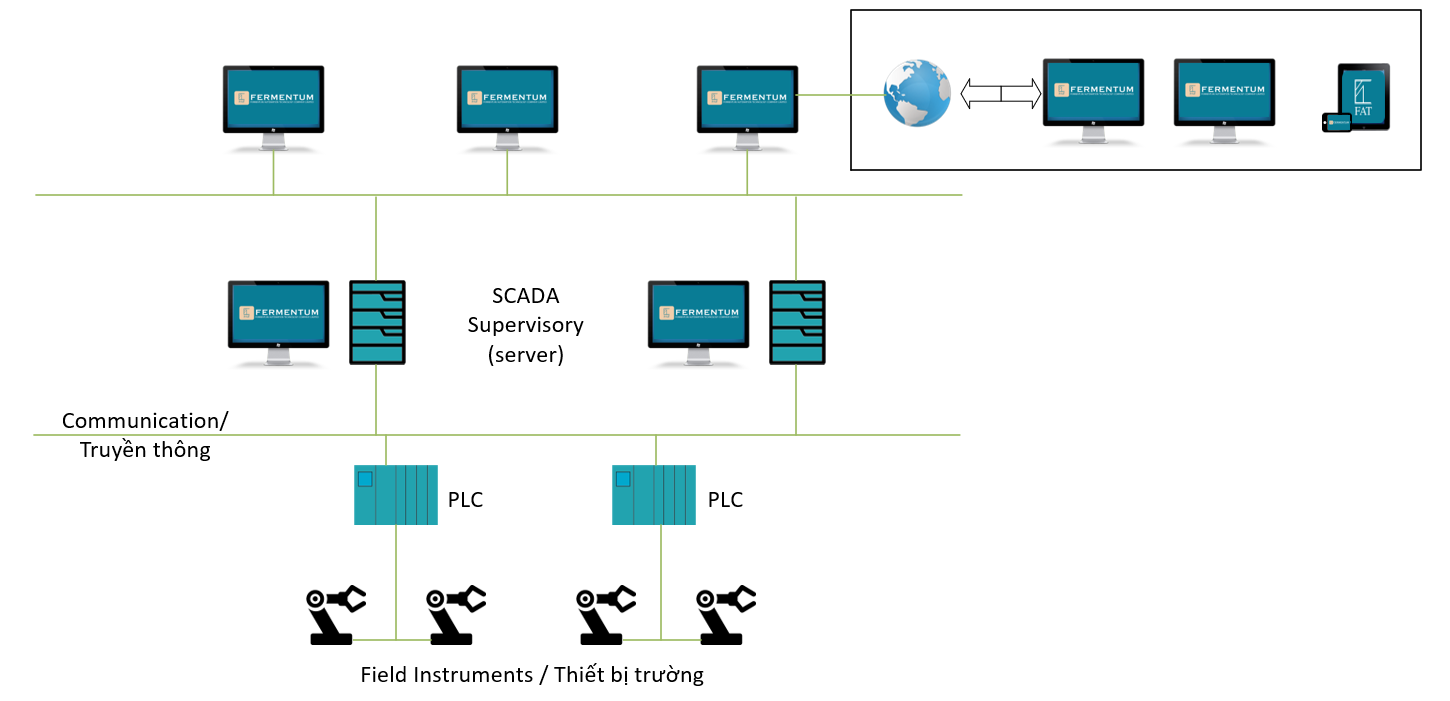

Cấu trúc hệ SCADA với modlue Dự phòng

Với hệ thống SCADA Redundancy (Dự phòng) mang đến cho người dùng cơ hội vận hành song song hai PC máy chủ WinCC được liên kết để giám sát lẫn nhau. Nếu một trong hai máy chủ bị lỗi hoặc gặp vấn đề thì máy chủ thứ hai sẽ đảm nhận quyền kiểm soát toàn bộ hệ thống. Khi máy chủ bị lỗi được khắc phục và hoat động trở lại, nội dung của tất cả các kho lưu trữ giá trị, thông số kỹ thuật và quy trình được được sao chép trở lại máy chủ được khôi phục. Phương án này không chỉ áp dụng cho vấn đề máy chủ bị lỗi, nhưng còn khắc phục vấn đề bị lỗi truyền thông. Đây sẽ là một lựa chọn thông minh và tối ưu cho những doanh nghiệp với quy mô lớn, cần sự hoạt động liên tục.

Bên cạnh đó, còn rất nhiều cấu trúc khác tương thích với từng nhu cầu của doanh nghiệp. Tùy thuộc vào nhu cầu của Qúy khách, cấu trúc mạng điều khiển hiện hữu và quy mô của Doanh nghiệp, để lựa chọn cấu trúc hệ thống SCADA tối ưu nhất.

Các ngành công nghiệp có ứng dụng SCADA bao gồm:

- Sản xuất công nghiệp

Đây là lĩnh vực ứng dụng hệ thống SCADA phổ biến nhất trong việc quản lý dây chuyền sản xuất, quy trình sản xuất và kiểm soát chất lượng sản phẩm. Hệ thống SCADA quản lý, điều khiển dây chuyền sản xuất, các máy móc, robot để sản xuất đúng lúc và triển khai tự động hóa công nghiệp. Hệ thống SCADA giúp đối đa hóa lợi nhuận, tăng hiệu quả quán lý nhà máy, nâng cao chất lượng nhà máy và chất lượng sản phẩm.

- Phát điện, truyền tải và phân phối điện

Các công ty điện lực sử dụng RTU (hoặc PLC) và SCADA để phát hiện dòng điện và điện áp đường dây của các địa điểm xa xôi. Trong lĩnh vực này hệ thống SCADA còn được sử dụng để giám sát hoạt động của máy cắt cho phép người vận hành bật hoặc tắt lưới điện từ xa. Vì vậy, hệ thống SCADA được sử dụng phổ biến tại các nhà máy phân phối điện từ khí đốt, than, hạt nhân, truyền tải và phân phối điện, v.v.

- Nước và xử lý nước thải

Hệ thống SCADA trong lĩnh vực cung cấp, quản lý nước hoặc xử lý nước thải. Chúng giám sát và điều chỉnh lưu lượng nước, mực nước trong hồ chứa, áp suất đường ống, cơ sở thu gom và xử lý nước thải, trung tâm xử lý và phân phối nước, cùng các yếu tố khác của thiết bị tại hiện trường.

- Các tòa nhà, cơ quan và môi trường

Các nhà quản lý cơ quan sử dụng SCADA để giám sát và điều khiển hệ thống HVAC, cảm biến nhiệt độ, thiết bị làm lạnh, hệ thống chiếu sáng và lối vào.

- Giao thông công cộng

Các cơ quan quả lý hệ thống giao thông sử dụng các chức năng của hệ thống SCADA để điều chỉnh điện ở các địa điểm xa xôi. Hệ thống SCADA điều khiển tự động hóa tín hiệu giao thông, theo dõi và định vị tàu hỏa và xe buýt, và để kiểm soát các cổng giao cắt đường sắt.

- Tín hiệu giao thông

SCADA điều chỉnh đèn giao thông, kiểm soát lưu lượng giao thông và phát hiện tín hiệu không theo thứ tự.

- Dầu khí

Các ứng dụng phần mềm SCADA được sử dụng để giám sát và kiểm soát từ xa các thiết bị liên quan đến đường ống, máy bơm, kho chứa, giàn khoan ngoài khơi và giếng trên bờ, nhà máy lọc dầu và trạm hóa dầu, v.v.

- Ngành năng lượng tái tạo

Các nhà máy năng lượng tái tạo sử dụng các thiết bị SCADA để giám sát và kiểm soát từ xa nhiều nhà máy năng lượng tái tạo khác nhau, bao gồm gió, mặt trời và thủy điện. Các thiết bị SCADA cung cấp hiệu quả nâng cao và bảo trì được cải thiện trong khi tuân thủ các quy định và tạo điều kiện cho sự phát triển trong tương lai.

- Sản xuất thực phẩm và đồ uống

Việc duy trì nhiệt độ trong phạm vi thích hợp là rất quan trọng khi sản xuất và chế biến thực phẩm. Hệ thống SCADA sẽ được sử dụng để giám sát và kiểm soát nhiệt độ trong các cơ sở này.

Tại sao lại chọn FERMENTUM?

Đội ngũ chúng tôi, với kinh nghiệm đã thiết kế và cung cấp Hệ thống SCADA cho các dự án lớn thuộc các Doanh nghiệp trong và ngoài nước. Chúng tôi luôn đặt các tiêu chí bảo mật, an toàn và hoạt động ổn định của hệ thống lên hàng đầu. Kết hợp với giá cả hợp lý và sự sẵn sàng nhiệt thành hỗ trợ khi Hệ thống của Qúy khách hàng gặp sự cố. Vì vậy, FERMENTUM luôn nhận được sự yêu mến và tin tưởng từ Khách hàng và đối tác.

Nếu Doanh nghiệp Qúy khách đang có nhu cầu thiết kế hệ thống SCADA riêng cho Doanh nghiệp, thì đừng ngần ngại liên hệ với chúng tôi.

Đội ngũ chúng tôi luôn hân hạnh được đón tiếp và phục vụ.