FERMENTUM

chuyên cung cấp dịch vụ lập trình PLC uy tín, chất lượng cao cho các

dự án công nghiệp. Chúng tôi lập trình PLC của các hãng, và cung cấp

dịch vụ lập trình PLC cho các tủ điều khiển máy móc, dây chuyền tự

động trong công nghiệp.

- Đội ngũ kỹ sư chuyên môn cao và

có nhiều kinh nghiệm lập trình PLC cho các dự án lớn

của các doanh nghiệp trong và nước ngoài.

- Tinh thần và tác phong làm việc

chuyên nghiệp và chân thành

- Quy trình làm việc chuyên nghiệp

và bài bản

- Dịch vụ hỗ trợ 27/7

- Bảo hành trọn đời chương trình PLC

PLC

là thiết bị điều khiển công nghiệp được sử dụng phổ biến hiện nay,

vì sự ổn định, tính bền bỉ của nó theo thời gian. PLC là thiết bị

cho phép người sử dụng các ngôn ngữ chuyên dụng để lập trình PLC theo

ý muốn.

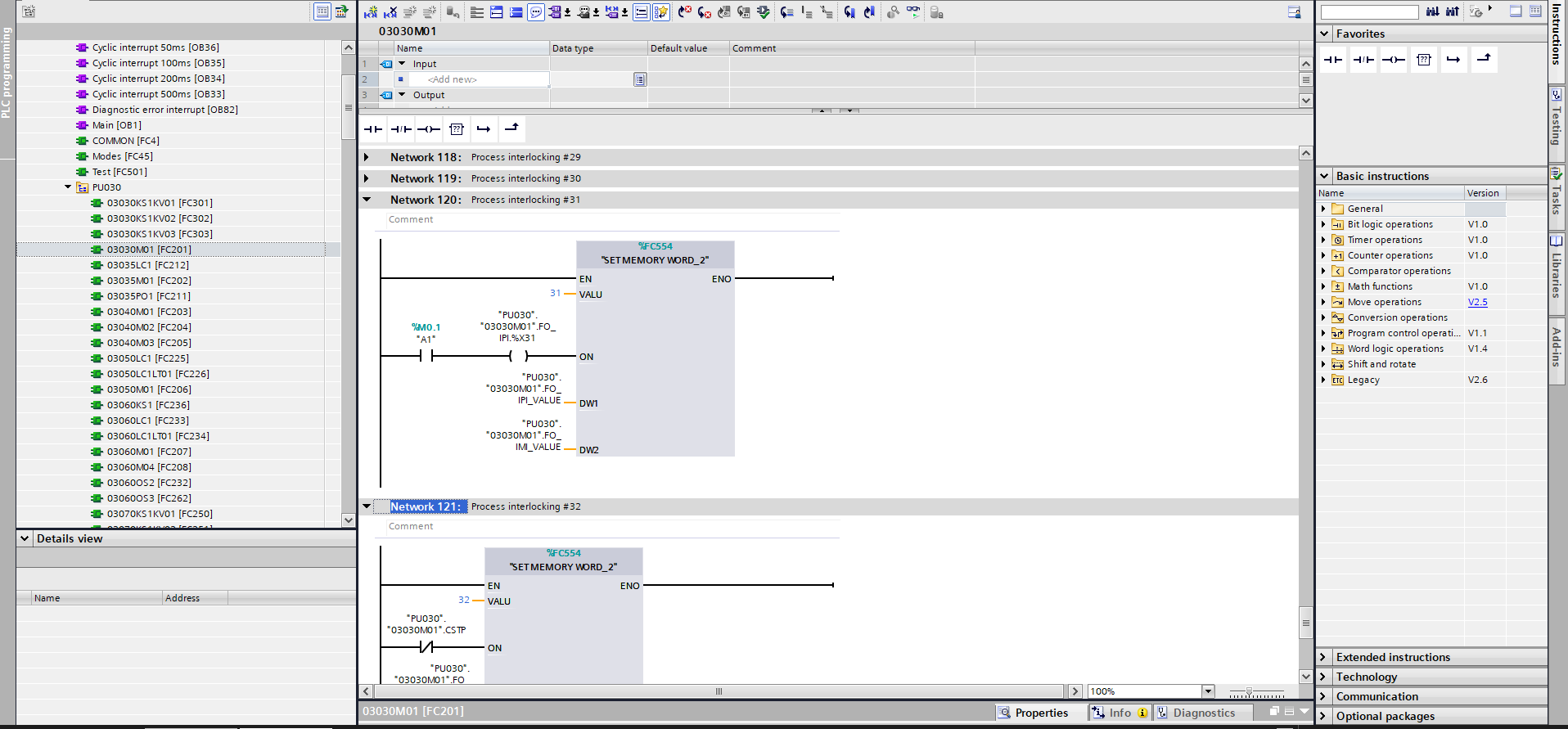

Lập

trình PLC là

việc sử dụng các ngôn ngữ chuyên dụng để lập trình cho PLC hoạt động

theo ý muốn của người dùng. Trọng tâm của việc lập trình PLC là để

điều khiển, giám sát chu trình sản xuất, máy móc tự động,…hoạt

động đúng với cơ năng của nó.

- Lập trình các dòng PLC tùy theo yêu cầu của khách hàng: PLC Siemens, PLC Mitsubishi, PLC Omron, PLC Delta, PLC Keyence

- Dịch vụ lập trình PLC của chúng tôi phục vụ cho đa lĩnh vực: Dây chuyền sản xuất liên tục, máy tự động, robot,…

- Hiêu chỉnh, nâng cấp và cải tiến trên chương trình PLC có sẵn.

- Lập trình và thiết kế HMI, hệ

thống SCADA với

các tính năng đa dạng và chuyên sâu. Một số tính năng phổ biến như:

+ Report: lưu trữ lịch sử vận hành của hệ thống (như các thông số kỹ thuật, thời gian vận hành, sản lượng, ….) và cho phép người dùng in ra thành bản cứng để lưu trữ.

+ Trending: Lưu trữ giá trị đo theo thời gian và hiển thị dưới dạng đồ thị để người vận hành dễ dàng giám sát đại lượng đo theo đồ thị. Như lượng nước sử dụng, năng lượng điện sử dụng….

+ Alarm: Hiển thị cảnh báo đến người vận

hành khi có lỗi xảy ra và hiển thị chính xác nguyên nhân, vị trí thiết

bị đang xảy ra lỗi. Với chức năng này, sẽ hỗ trợ rất nhiều cho đội

ngũ kỹ thuật trong quá trình bảo trì, sửa chữa và vận hành.

+ Event: Tính năng lưu lại lịch sử các

tác vụ của người vận hành.

+ Recipe: tính năng dùng để tạo, hiệu chỉnh,

lưu trữ, giám sát quá trình của các công thức sản xuất.

+ Phân

quyền người dùng: Hệ

thống SCADA là hệ thống phức tạp và đòi hỏi tính bảo mật cao. Vì

vậy, để bảo đảm an toàn thông tin, hệ thống sẽ phân quyền truy cập

cho người dùng, tùy theo chức vụ, vai trò của người dùng. Mỗi người

dùng chỉ được quyền truy cập vào các hệ thống đã được cho phép.

- Thiết

kế và sản xuất tủ điện điều khiển

- Hệ thống hoạt động ổn định,

đáp ứng nhanh và chính xác: Lập

trình PLC là lập trình cho hệ thống, cho quy trình sản xuất hay máy

móc tự động. Vì vậy, chương trình PLC phải đáp ứng được tiêu chí cơ

bản nhất là làm cho hệ thống, máy móc và quy trình đó hoạt động

ổn định, đáp ứng nhanh và chính xác.

- An toàn: Yếu tố an toàn luôn hệ

thống phải luôn được chú trọng và ưu tiên hàng đầu trong quá trình lập

trình PLC. Yếu tố an toàn được áp dụng cho an toàn hệ thống máy

móc, sản phẩm, thiết bị, nhưng quan trọng hơn là an toàn cho con

người. Vì vậy, các chức năng và chương trình trong PLC phải giành ưu

tiên cho vấn đề an toàn. Các nút nhấn khẩn cấp phải được bố trí

hợp lý, dễ thấy, dễ vận hành nhất.

- Chương trình PLC logic, rõ ràng: Chương trình PLC logic, rõ

ràng sẽ giúp cho các kỹ sư, đội ngũ kỹ thuật của nhà máy sau khi

tiếp nhận có thể dễ dàng đọc hiểu.

- Các tính năng đầy đủ trên HMI,

SCADA

- Độ bảo mật: Đây là yếu tố vô cùng quan

trọng trong quá trình lập trình PLC, thiết hệ thống SCADA. Độ bảo

mật cao sẽ giúp doanh nghiệp tránh các sự cố về hack hệ thống, nguy

cơ bị sự can thiệp bởi bên ngoài, mất thông tin,…

- Giao diện HMI và SCADA logic, rõ

ràng và độ thẩm mỹ phù hợp với không gian công nghiệp. Đây là phần giao diện bên ngoài

cho người vận hành. Một giao diện HMI/SCADA logic, rõ ràng sẽ giúp

người vận hành tập trung hơn, dễ dàng quản lý và tránh những sai

sót trong quá trình vận hành.

- Chi phí phù hợp: Yếu tố cuối cùng đó là chi phí cho dịch vụ lập trình PLC phải phù hợp với ngân sách của bạn. Tuy nhiên, yếu tố này nên là vấn đề cân nhắc sau cùng khi quý khách lựa chọn dịch vụ lập trình PLC. Vì những lợi ích của các yếu tố kỹ thuật sẽ bù đắp và đem lại lợi nhuận gấp bội cho công ty trong tương lai.

Trên

đây là các thông tin quan trọng về dịch vụ lập trình PLC của

chúng tôi. Chúng tôi hy vọng các thông tin trên sẽ giúp ích cho quý

khách trong quá trình tìm hiểu và lựa chọn nhà cung cấp dịch vụ

lập trình PLC phù hợp.

Nếu

quý khách có nhu cầu về dịch vụ lập trình PLC cho các dự án

công nghiệp, hay cải tiến chương trình PLC thì đừng

ngần ngại liên hệ với chúng tôi nhé. Chúng tôi luôn sẵn sàng lắng

nghe và rất hân hạnh được phục vụ quý khách.