Dây cáp điện công nghiệp là một trong những hạng

mục quan trọng và không thể thiếu trong quá trình xây dựng và vận

hành nhà máy, tổ chức. Chính vì vậy, vấn đề chất lượng và tiêu

chuẩn kỹ thuật của cáp điện luôn được đặt lên ưu tiên khi doanh nghiệp

xây dựng nhà máy. Điều đó không chỉ giúp nhà máy vận hành ổn định,

an toàn mà còn giảm thiếu chi phí bảo trì, bảo dưỡng và giảm thiếu

sự cố hư hỏng trong quá trình sử dụng. Vậy những lưu ý nào khi lựa

chọn cáp điện công nghiệp? Cách thi công, lắp đặt cáp điện công

nghiệp đúng chuẩn? Hay nên mua cáp điện của hãng nào và ở đâu? Hãy

cùng FERMENTUM tìm hiểu ngang qua bài viết sau đây nhé!

Có nhiều cách phân loại các loại dây cáp điện công nghiệp khác nhau. Tuy nhiên, chúng tôi chỉ giới thiệu những cách phân loại chính được sử dụng phổ biến bao gồm:

Phân loại dây cáp điện điện theo vật liệu làm ruột dẫn

- Cáp đồng

- Cáp nhôm

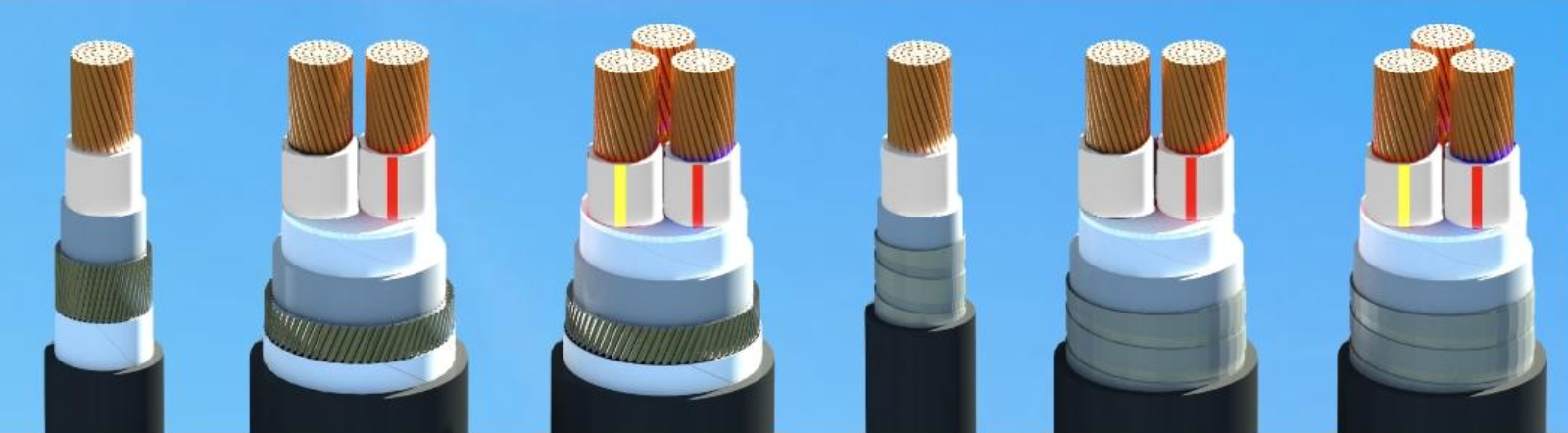

Phân loại theo số lượng ruột dẫn

Cách phân loại này dựa vào số lượng ruột dẫn trong cáp điện để phân loại.

- Dây đơn: Ruột chỉ gồm 1 lõi dẫn điện

- Dây đôi: Gồm 2 lõi dẫn điện

- Dây ba: Gồm 3 lõi dẫn điện

- ….

Phân loại theo ứng dụng của dây cáp điện

Cách phân biệt này dựa vào các yêu cầu kỹ thuật của cáp điện đối với môi trường và đối tượng sử dụng của cáp điện.

- Cáp điện lực: Được sử dụng trong các trường hợp cung cấp nguồn điện cho thiết bị, như hệ chiếu sáng, động cơ, tủ điện…

- Cáp điều khiển: Được sử dụng trong các trường hợp cung cấp tín hiệu điều khiển từ trung tâm điều khiển đến các thiết bị cảm biến và cơ cấu chấp hành. Cáp điện điều khiển có nhiều lõi tùy theo nhu cầu tín hiệu của thiết bị.

- Dây cáp điện trần: Dùng cho đường truyền tải trên không, dây nối đất, dây chằng, dây chống sét.

- Cáp điện lực chậm cháy, chống cháy: Dùng cho hệ phân phối điện hạ thế, có độ kháng mài mòn cao, môi trường khắc làm việc nguy hiếm, dễ cháy nổ.

- Cáp điện lực trung thế: Dùng cho hệ thống phân phối điện trung thế

Nội dung này giúp quý khách hiểu thêm đặc tính kỹ thuật của dây cáp điện, để phục vụ trong quá trình lựa chọn cáp điện phù hợp với yêu cầu bài toán đưa ra.

Nội dung này giúp quý khách hiểu thêm đặc tính kỹ thuật của dây cáp điện, để phục vụ trong quá trình lựa chọn cáp điện phù hợp với yêu cầu bài toán đưa ra.

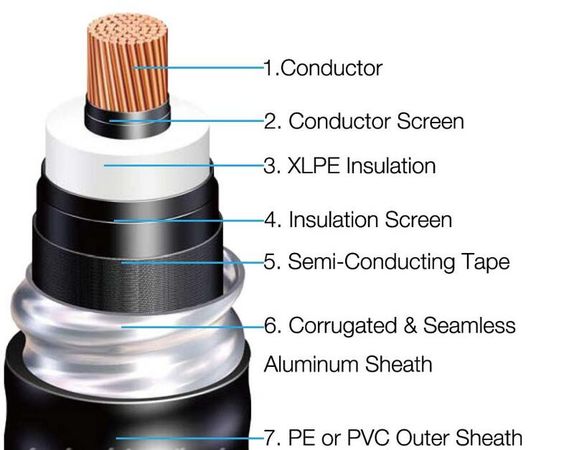

Các ký hiệu dựa trên thành phần cấu tạo của dây cáp điện công nghiệp:

- Cu - cuprum: Vật liệu đồng

- Al- aluminum: Vật liệu nhôm

- PVC - Polyvinyl Chloride: là chất cách nhiệt dẻo được sử dụng phổ biến nhất cho các loại dây và cáp điện.

- PE – Polyethylenec: PE được chứng minh là có những đặc điểm nổi bật sử dụng rất tốt làm vật liệu cách điện, nhờ đặc tính cách điện tốt; cơ tính tốt, ổn định và chống lại các hiện tượng phân hủy hóa học. Tuy nhiên, Những liên kết chuỗi mạch thẳng của các phân tử polyethylene lỏng lẻo dễ bị bẻ gãy khi gặp phải nhiệt độ trên 70°C. Vì vây, PE hạn chế sử dụng cho những môi trường nhiệt độ cao.

- XLPE – Cross-Linked Polyethylene

- DATA, DSTA, SWA: Các lớp bảo vệ, chống nhiễu. Mỗi lớp có những chức năng, ưu nhược điểm khác nhau. Qúy khách vui lòng tìm hiểu thêm để lựa chọn phù hợp nhé

- FR - Fire-Resistant: Chống cháy

Khi lựa chọn cáp điện, khách hàng cần xem xét những yếu tố sau:

- Dòng điện định mức: Yếu tố này chạy trong ruột cáp thì sẽ sinh nhiệt cho cáp nóng lên. Khi nhiệt độ cáp vượt mức cho phép thì phải chọn cáp có tiết diện ruột dẫn lớn hơn.

- Độ sụt áp: Độ sụt áp phụ thuộc vào, dòng điện tải, hệ số công suất, chiều dài cáp, điện trở cáp và điện phản kháng. Theo tiêu chuẩn IEE 522-8 quy định độ sụt áp không vượt quá 2,5% điện áp danh nghĩa.

- Dòng diện ngắn mạch

- Cách lắp đặt

- Nhiệt độ môi trường hoặc nhiệt độ đất

Việc thi công, lắp đặt hệ thống dây cáp điện công nghiệp đóng vai trò là một mắt xích quan trọng trong quá trình thi công, lắp đặt nhà máy. Lắp đặt, thi công hệ thống cáp điện đảm bảo sẽ góp phần làm cho hệ thống được hoạt động ổn định, tuổi thọ cáp điện đảm bảo và đặc biệt là tránh những sự cố tiêu cực do cáp điện gây ra.

- Giai đoạn chuẩn bị: Trước khi lắp đặt cáp điện, cần hoàn thiện hệ thống giá đỡ cho cáp, thang máng cáp, ống điện, ống ngầm (nếu cáp điện đi ngầm). Các hệ thống này cần thi công đảm bảo tiêu chuẩn kỹ thuật.

- Kéo cáp điện công nghiệp: Trước lúc kéo cáp cần kiểm tra kỹ các đường đi của cáp điện. Tiến hành lót vải, con lăn tại các vị trí gấp khúc, hoặc vị trí có khả năng làm hỏng cáp. Trong quá trình kéo cáp phải cận thận, tránh trường hợp làm hỏng cáp điện.

- Xếp cáp điện: Cần xếp cáp gọn gàng, logic, tránh chồng chéo. Đặc biệt đối với cáp điện động lực lớn, thì cách xếp cáp động lực cần phải tuân thủ các tiêu chuẩn riêng.

- Kiểm tra cáp điện công nghiệp: Tiến hành kiểm tra vị trí đấu nối của cáp điện đã đúng địa chỉ theo bản vẽ. Tiến hành kiếm tra cách điện đối với cáp động lực.

Vì là hạng mục quan trọng, nên việc đảm bảo tiêu chí chất lượng của cáp điện công nghiệp luôn được ưu tiên hàng đầu. Để đảm bảo điều đó, khách hàng nên lựa chọn cáp điện từ những thương hiệu uy tín hàng đầu hiện nay, tiêu biểu gồm: Dây cáp điện Cadivi (Việt Nam); Dây cáp điện LS-Vina (Hàn Quốc); Dây cáp điện Helukabel (Đức); Dây cáp điện Taihan (Hàn Quốc),...

Để tiết kiệm thời gian và chi phí, quý khách hàng có thể cân nhắc dịch vụ thiết kế, cung cấp và lắp đặt hệ thống cáp điện công nghiệp bên chúng tôi. Với đội ngũ kỹ sư chuyên môn cao và có kinh nghiệm thực hiện nhiều dự án lớn cho các doanh nghiệp trong và nước ngoài. Cùng với tinh thần, tác phong làm việc chuyên nghiệp, chân thành và quy trình làm việc bài bản. Chúng tôi sẽ mang lại cho quý khách sự an tâm và sự hài lòng khi sử dụng dịch vụ chúng tôi.

Vì vậy, quý khách hàng có nhu cầu về dây cáp điện công nghiệp, hoặc đang tìm kiếm nhà thầu cung cấp và lắp đặt hệ thống dây cáp điện công nghiệp. Thì đừng ngần ngại liên hệ với chúng tôi, chúng tôi luôn sẵn sàng lắng nghe và hân hạnh được phục vụ quý khách.